Performance and application process of potting glue

Sealing adhesive is a widely used protective material in the manufacturing of electronic components, providing a solid guarantee for the long-term stable operation of electronic products with its excellent performance. It forms a dense protective layer by coating or sealing the surface of electronic components, which can effectively prevent the invasion of moisture, dampness, dust, and corrosive substances, thereby significantly improving the waterproof, moisture-proof, dustproof, and anti-corrosion capabilities of electronic components and extending their service life.

Performance of sealing adhesive

Waterproof and moisture-proof: After the sealing adhesive is cured, it can effectively prevent the invasion of moisture and dampness, and improve the waterproof and moisture-proof performance of electronic components.

Dust and corrosion prevention: After curing, the sealing adhesive will form a dense protective layer, which can effectively block the invasion of dust and corrosive substances, and extend the service life of electronic components.

Insulation and thermal conductivity: The potting adhesive has excellent insulation properties and can effectively prevent electrical short circuits. Some sealing adhesives also have good thermal conductivity, which helps with heat dissipation.

Shock and pressure resistance: Encapsulation glue can enhance the overall integrity of electronic devices and effectively resist the effects of external impacts and vibrations. At the same time, by reinforcing the internal structure, the compressive performance of electronic devices can be enhanced, ensuring that electronic devices can maintain stable operation in various harsh environments.

Temperature and weather resistance: The sealing adhesive can withstand high and low temperature changes within a certain range, and some products can even maintain stable performance at extreme temperatures. It also has good weather resistance and can resist degradation by ozone and ultraviolet radiation.

The process of using sealant

Surface treatment: Clean the surface of the circuit board that needs to be sealed to remove impurities such as dust, oil, and moisture, ensuring that the surface is dry, clean, and flat.

Mixing and stirring: According to the product instructions, thoroughly mix and stir the main agent and curing agent of the sealant. Stir evenly to ensure the curing effect.

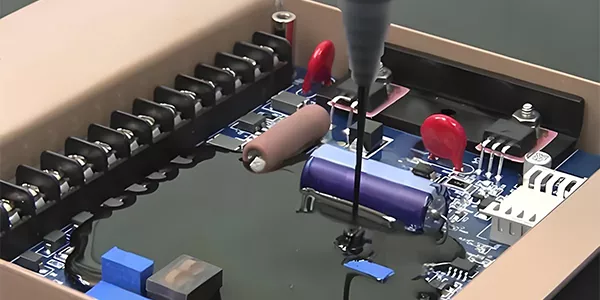

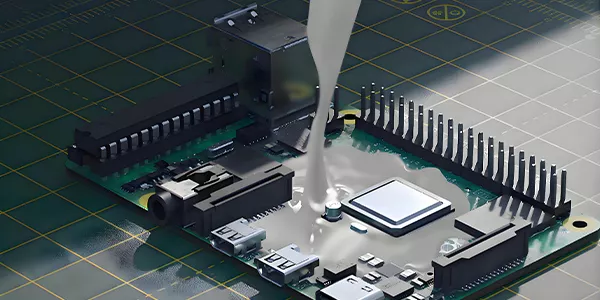

Pouring: Use appropriate tools such as syringes, glue guns, etc. to slowly and evenly pour the mixed sealing glue into the area that needs to be filled.

Exclude bubbles: Bubbles may be generated during the infusion process. Static placement, vacuum degassing, or vibration can be used to eliminate bubbles to ensure the quality of sealing.

Curing: Based on the characteristics and environmental conditions of the sealant, let it cure at an appropriate temperature and humidity. The curing time varies depending on the product and must be strictly followed according to the instructions.

Repair: After curing is completed, inspect the sealing surface and, if necessary, repair and polish it.